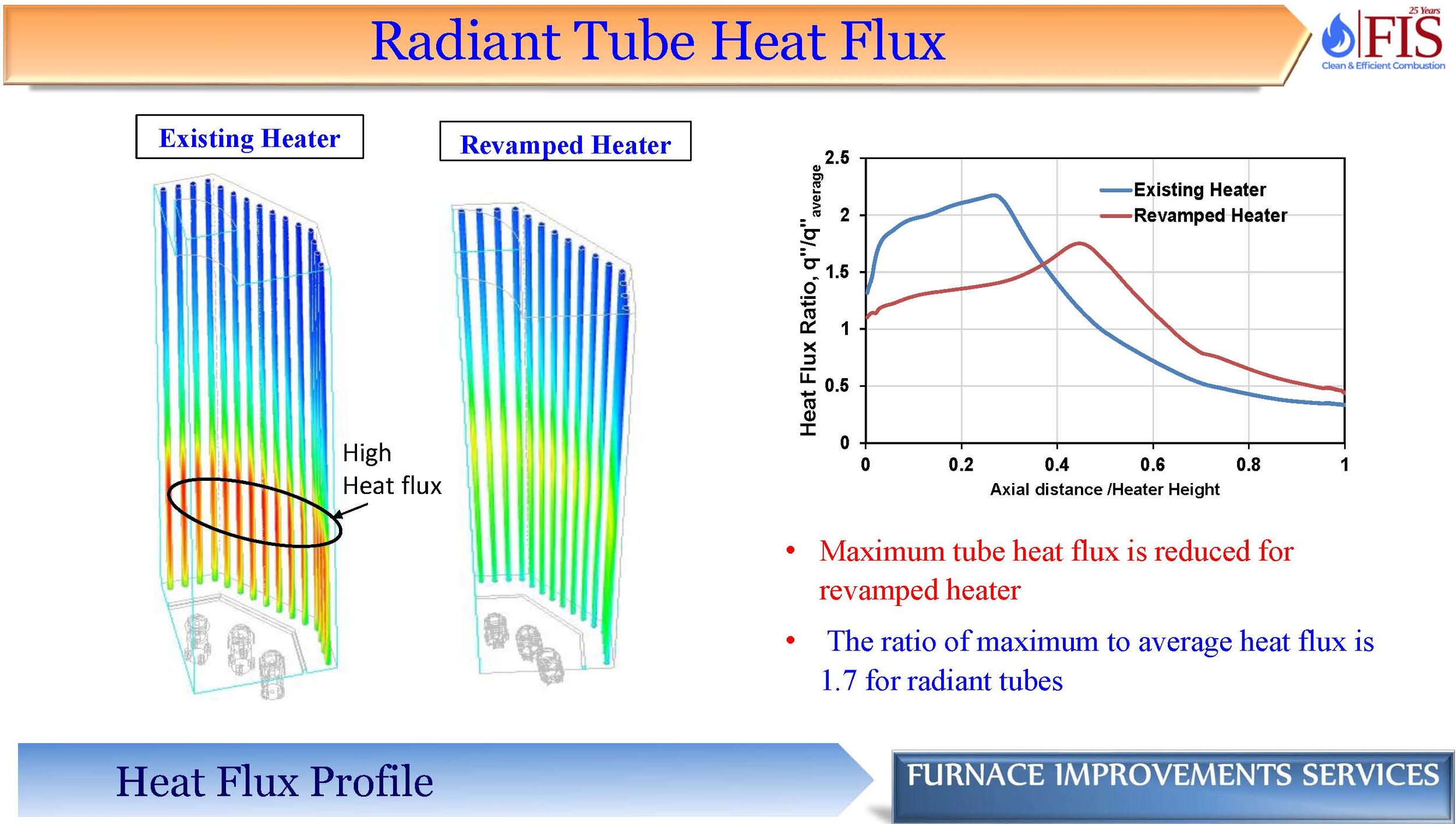

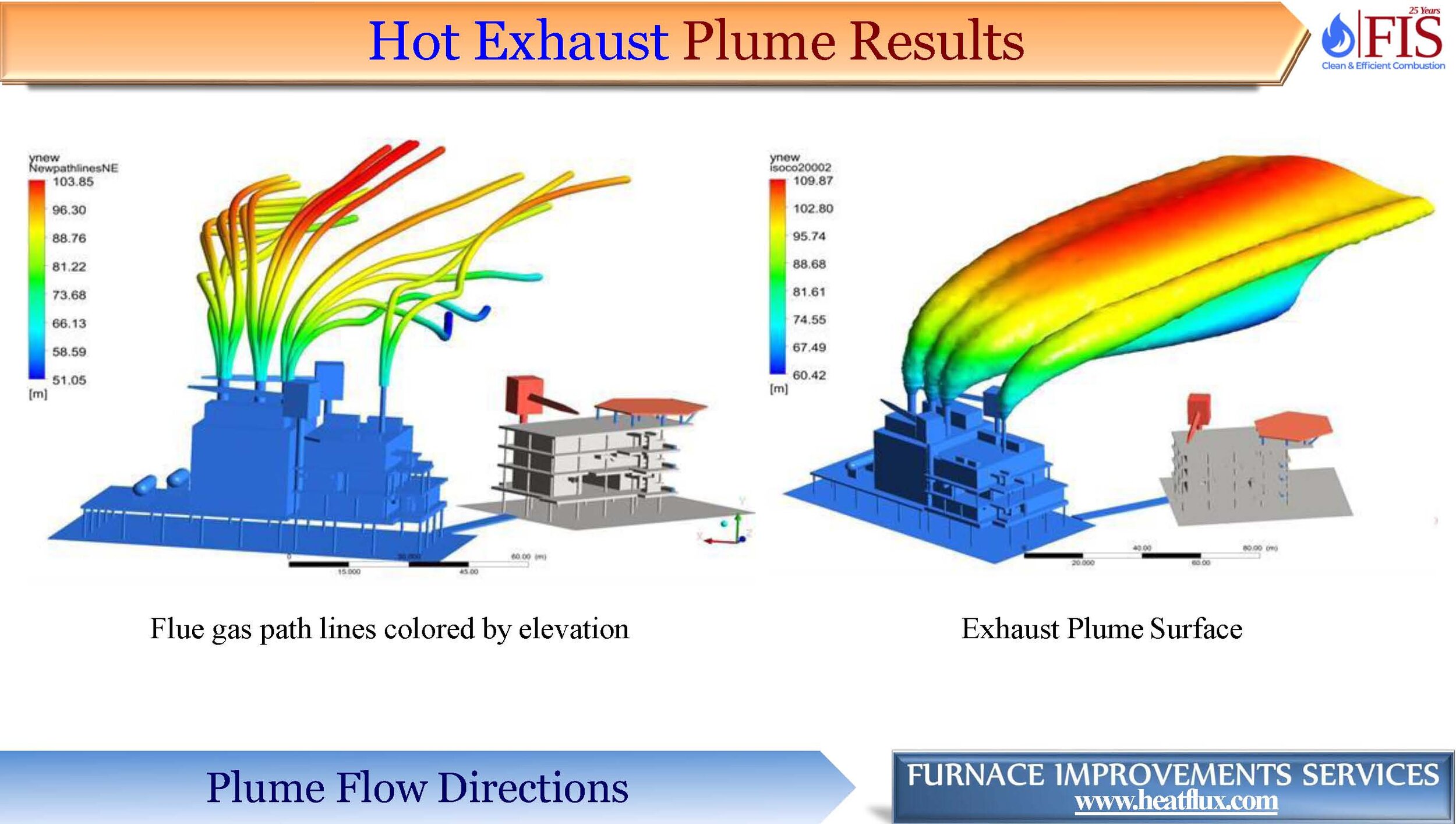

Computational Fluid Dynamics (CFD) modeling is an advanced simulation technology capable of performing detailed combustion analysis of burners to study the flow temperature profiles along with the flue gas circulation pattern in the heater. The simulation helps to understand the heater insights in terms of flue gas flow pattern, heat flux distribution over radiant tubes, tube metal temperatures, and temperature distribution in the heater.

At Furnace Improvements, we utilize CFD to study the design and operating conditions of heaters, locate problems, and provide solutions.

This Includes:

Evaluation of burner configurations to improve heater performance

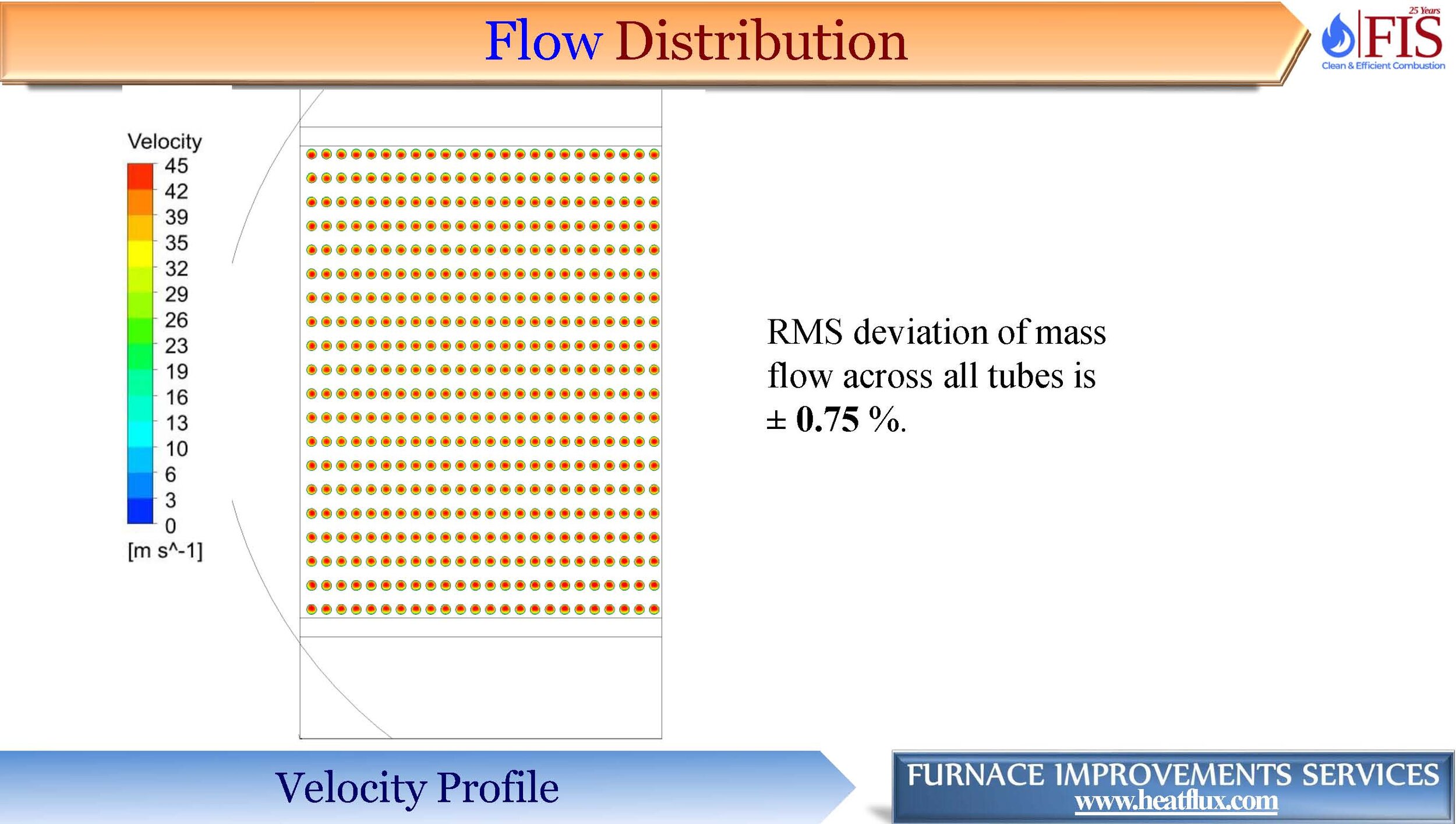

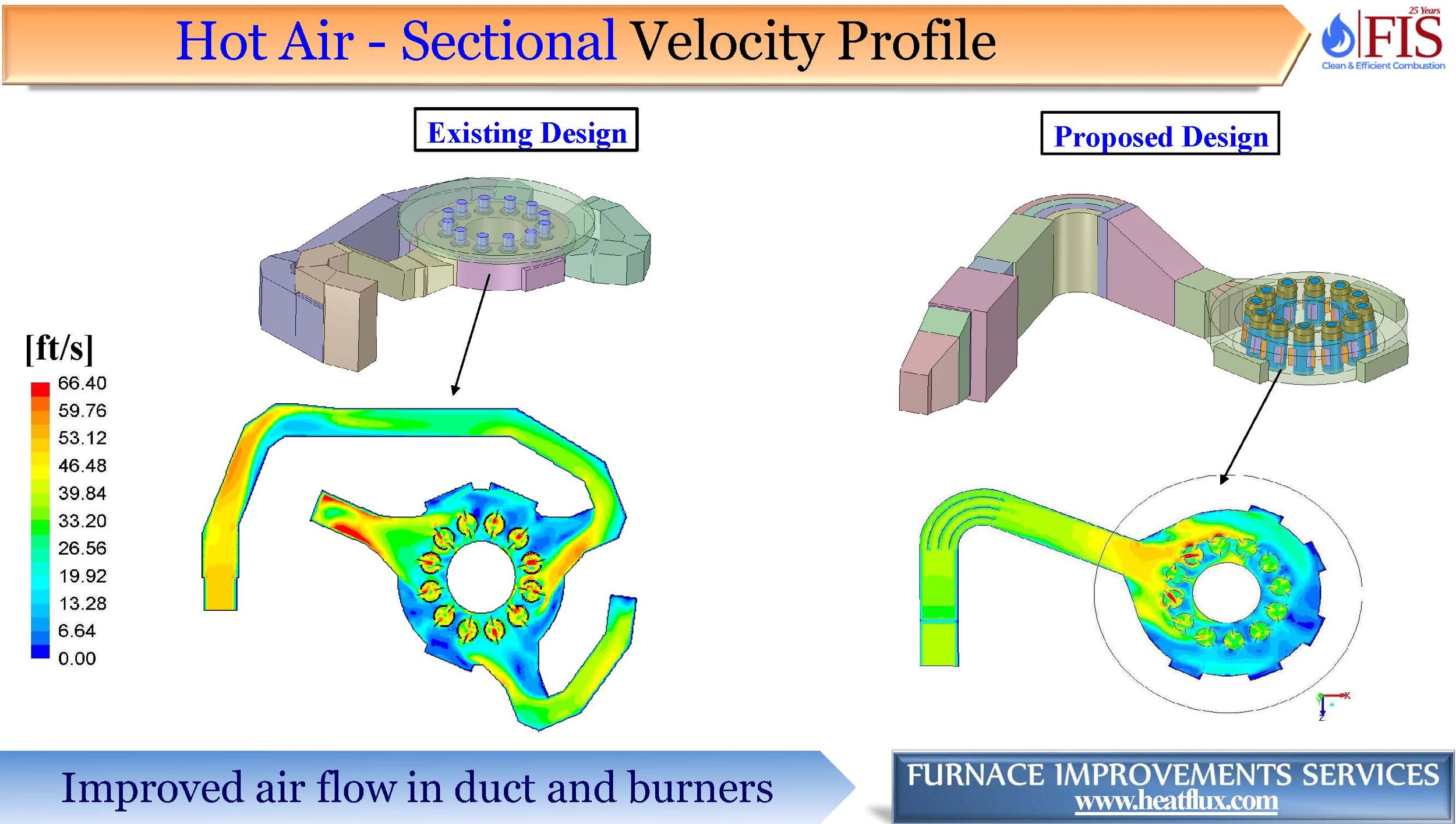

Uniform airflow distribution across all burners

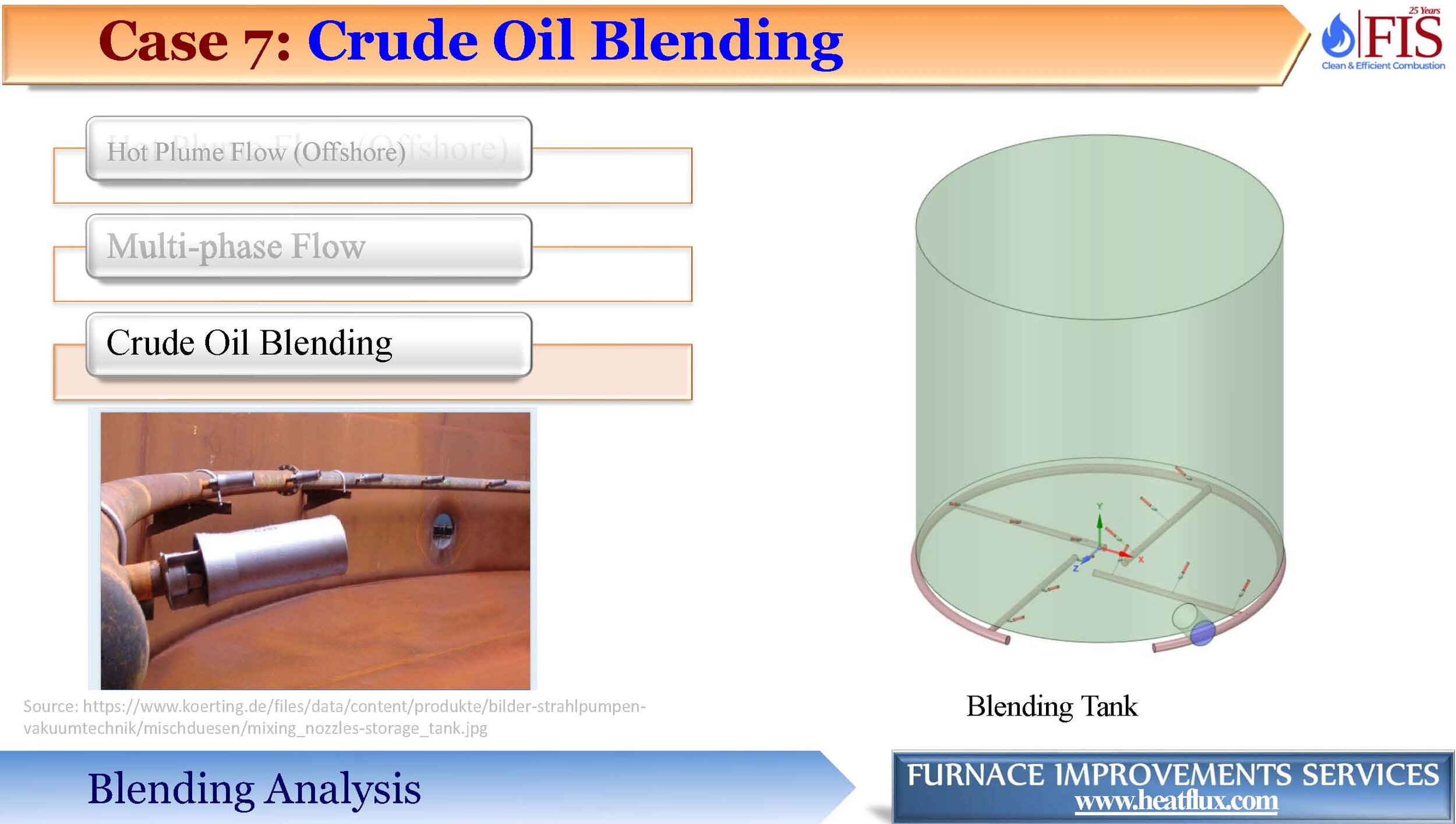

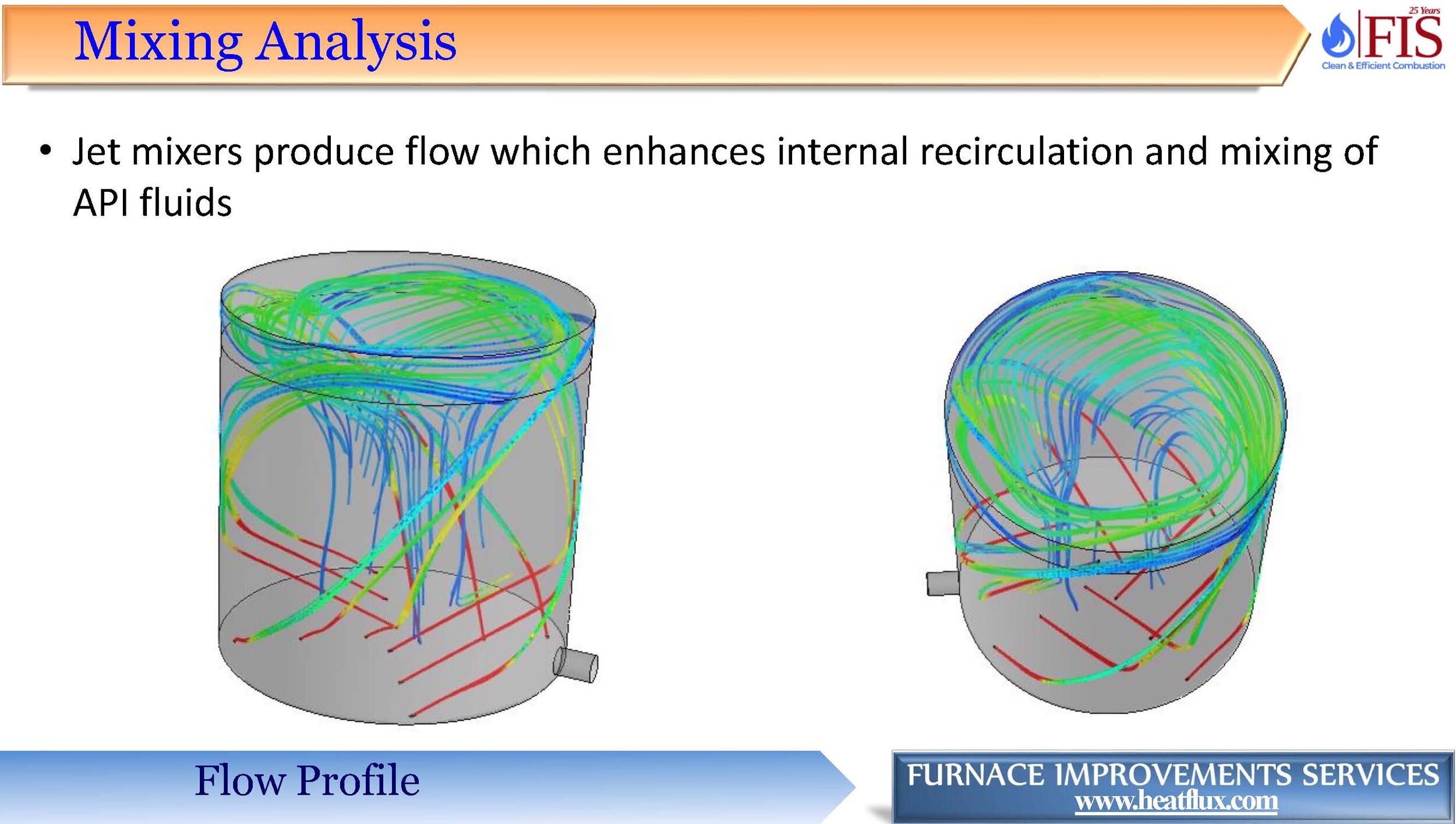

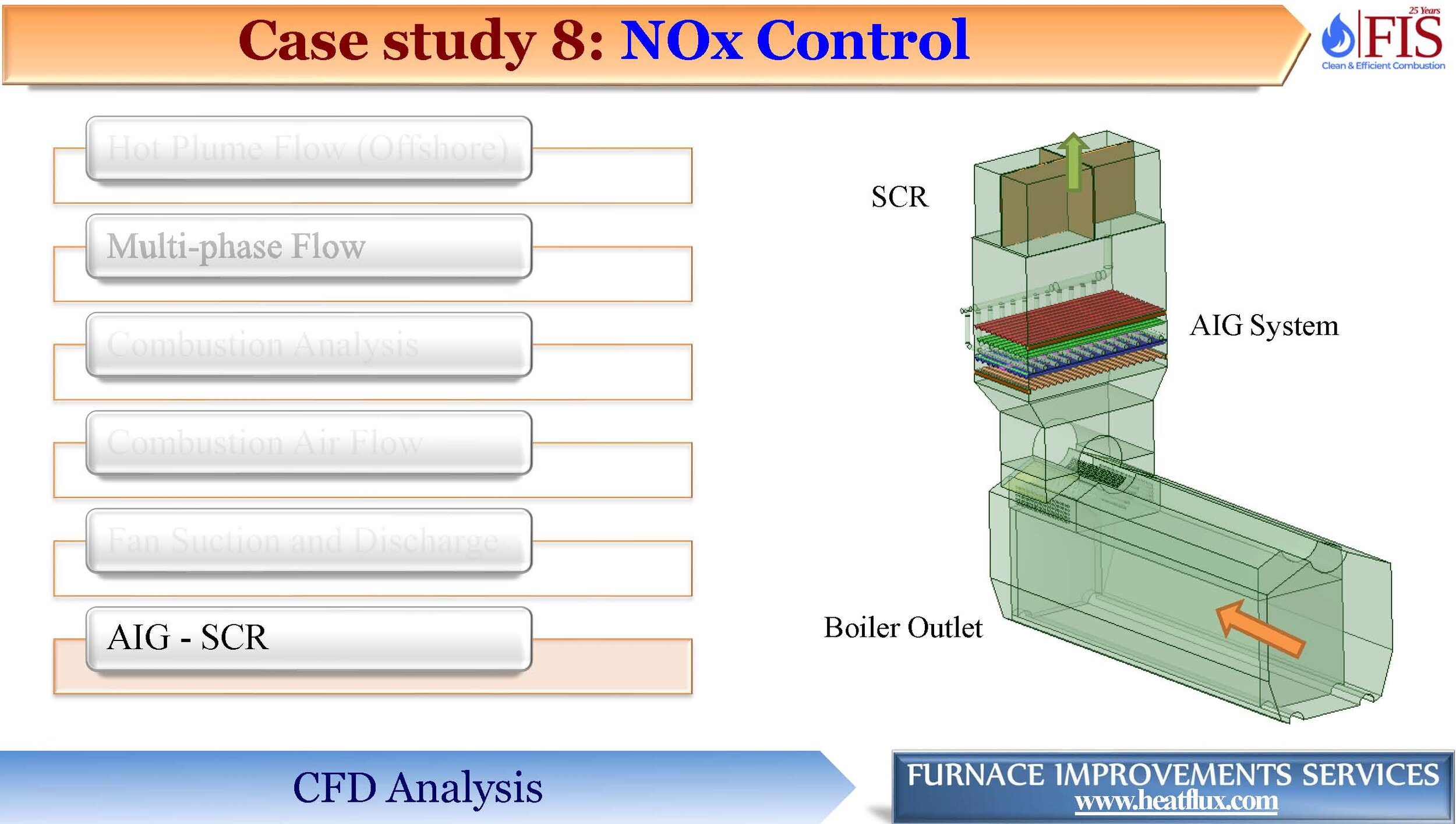

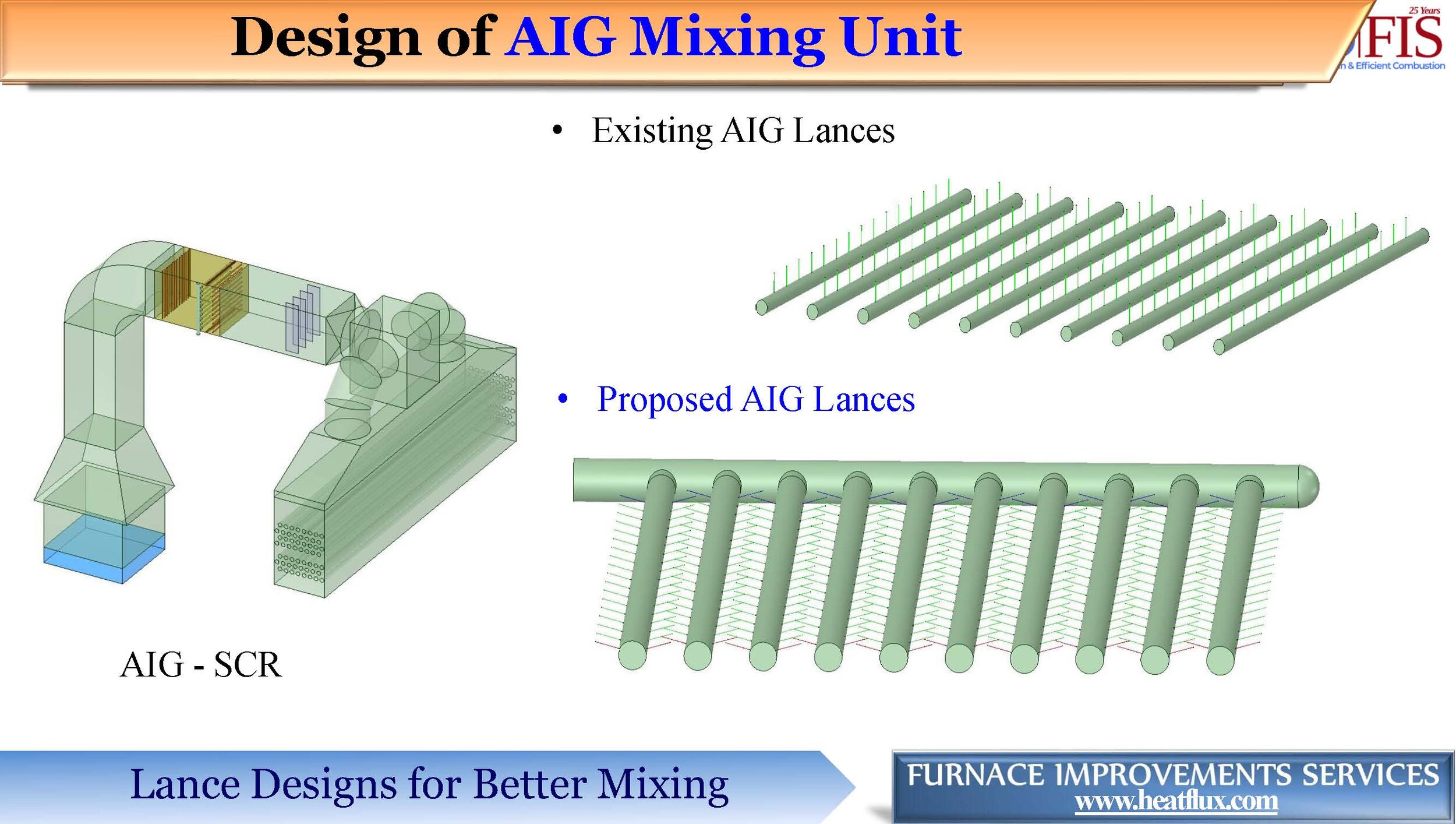

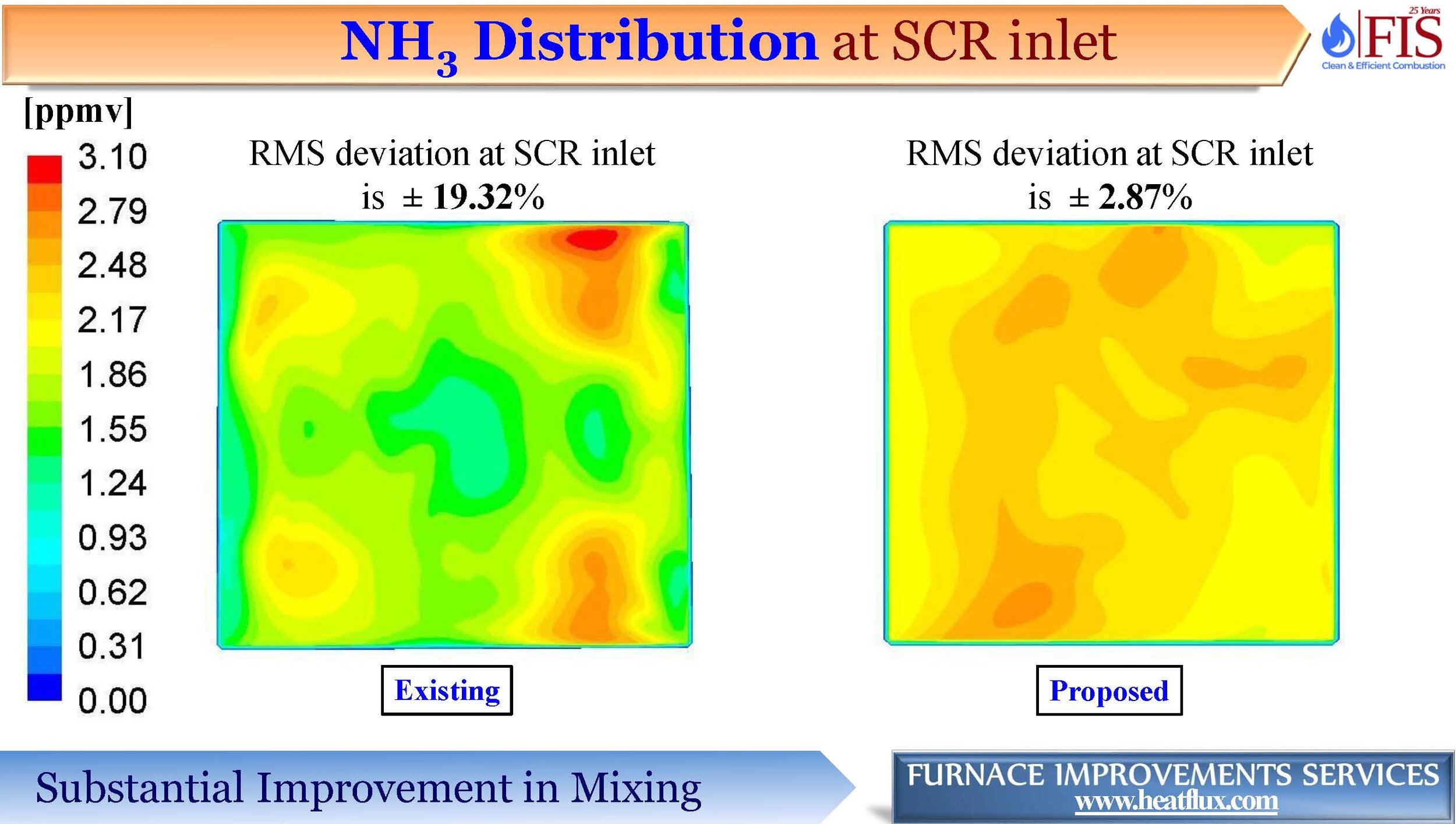

Design of Ammonia Injection Grid to have uniform mixing

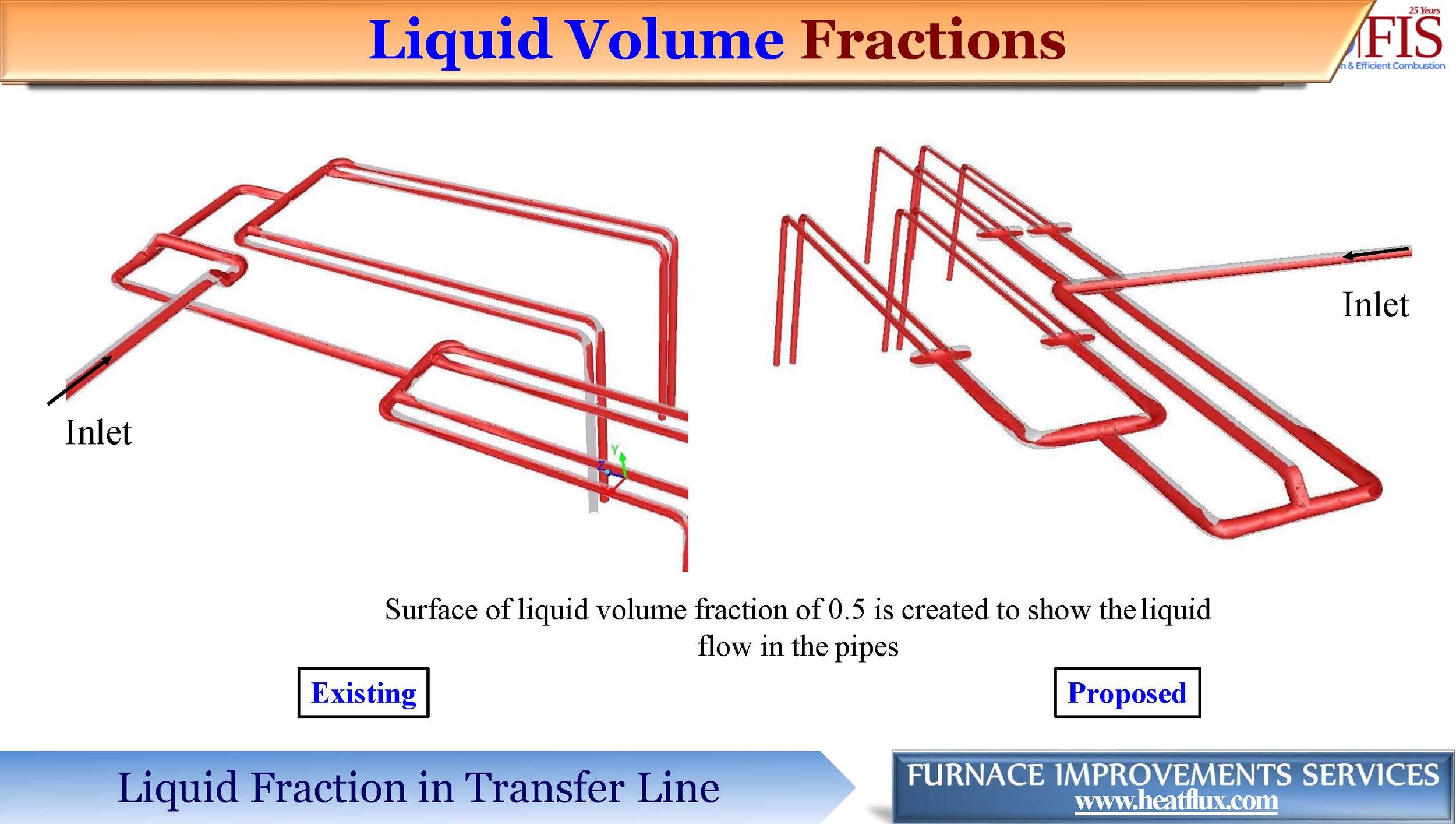

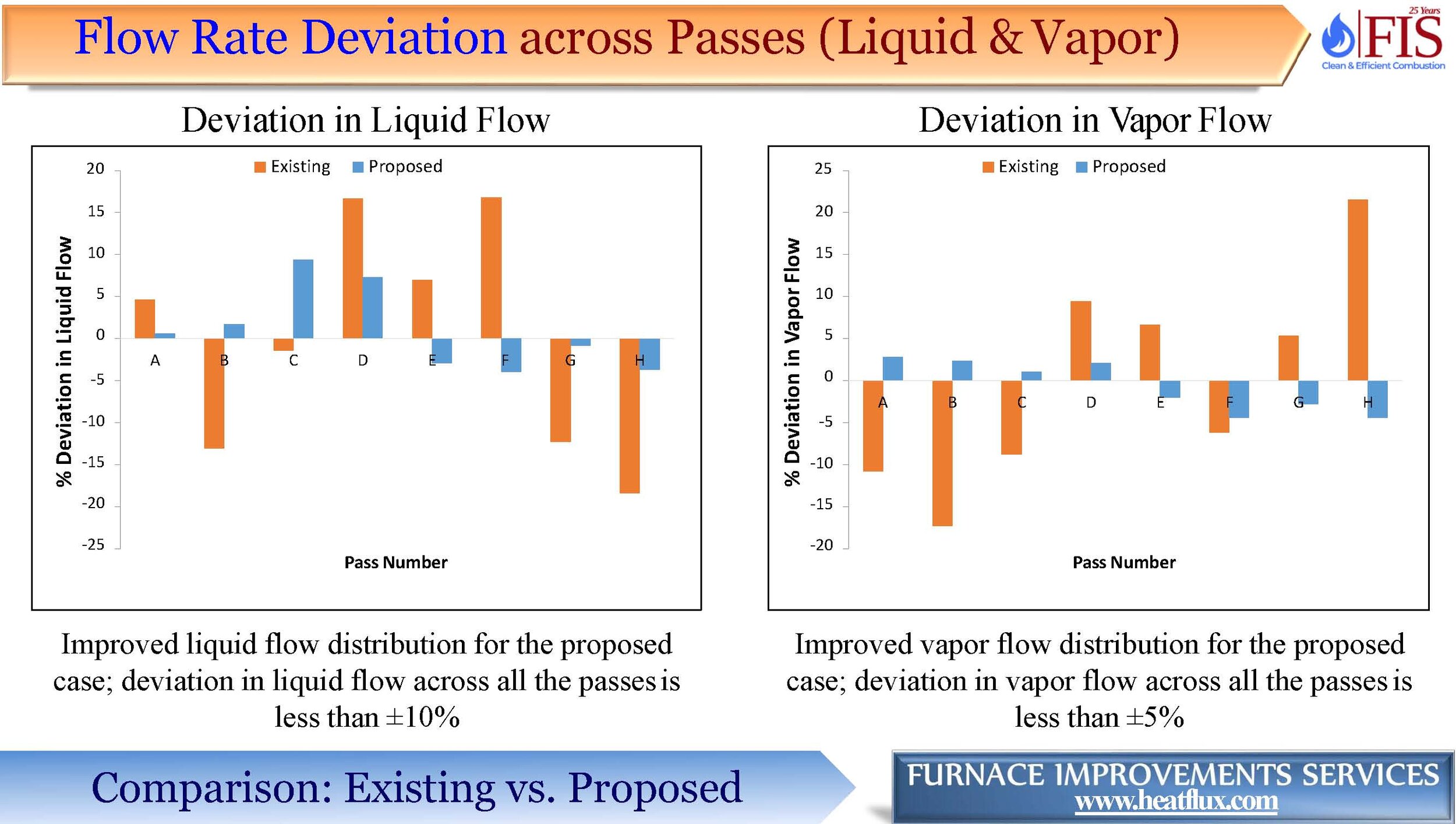

Uniform process fluid distribution across transfer lines

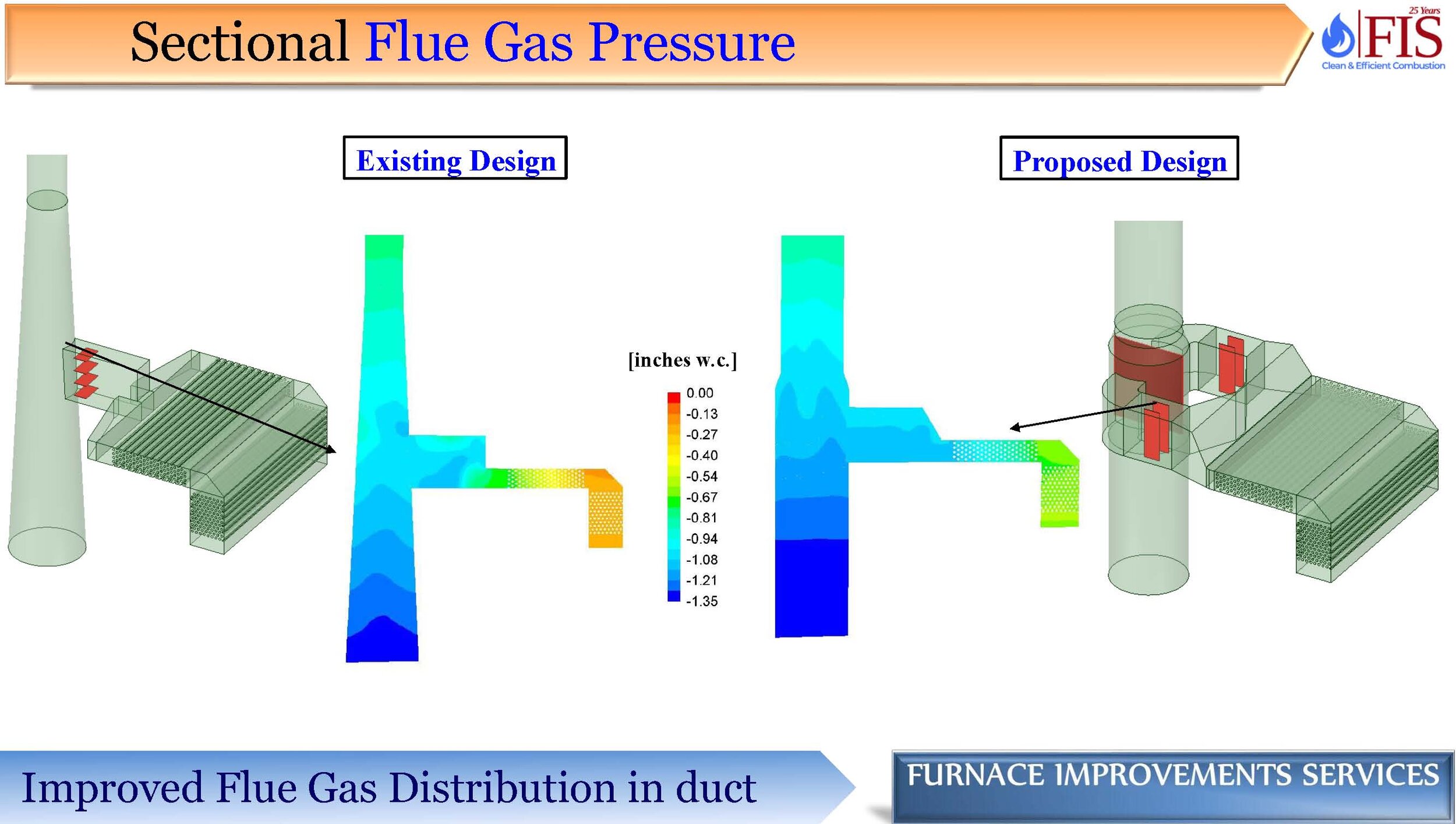

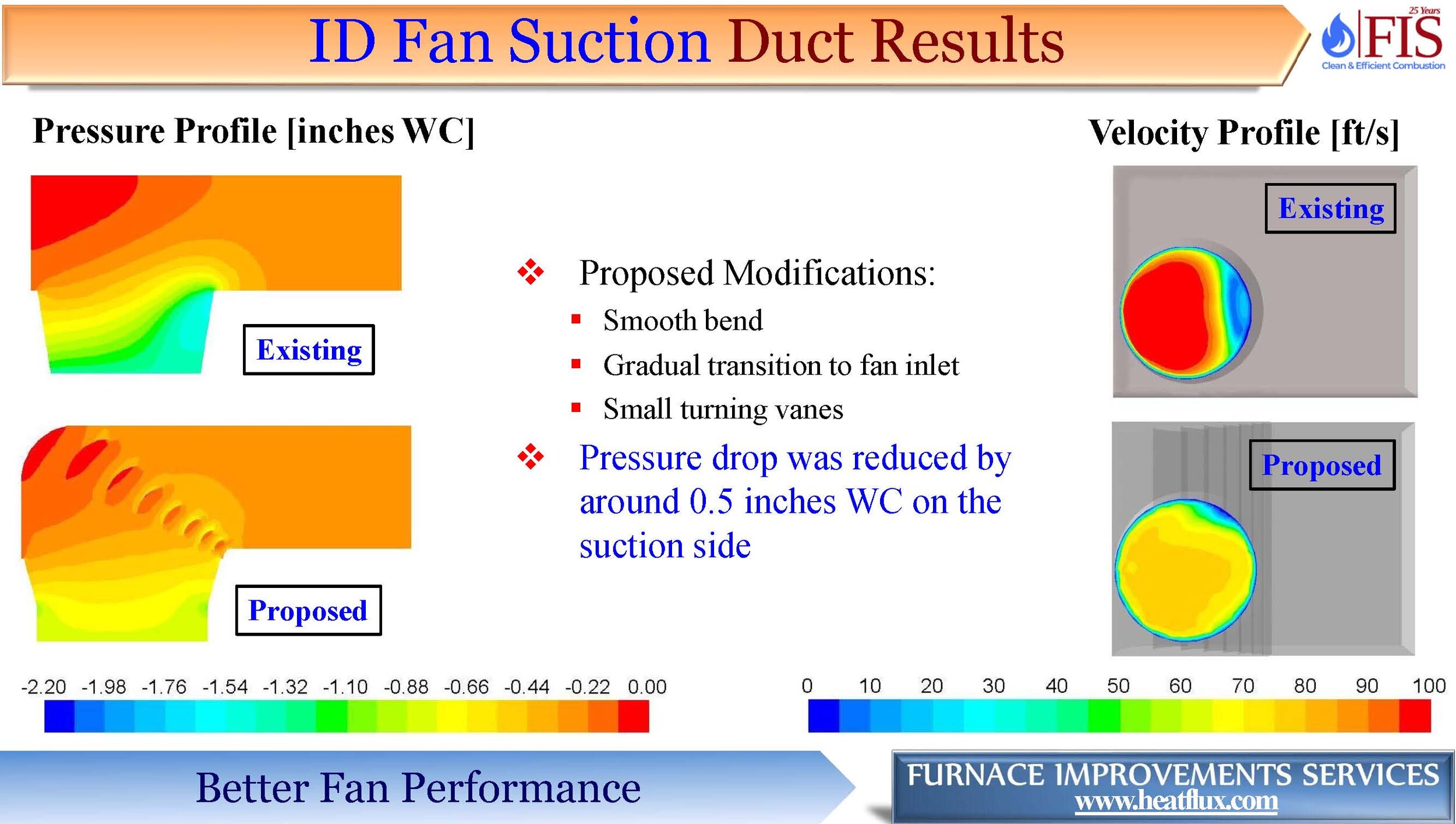

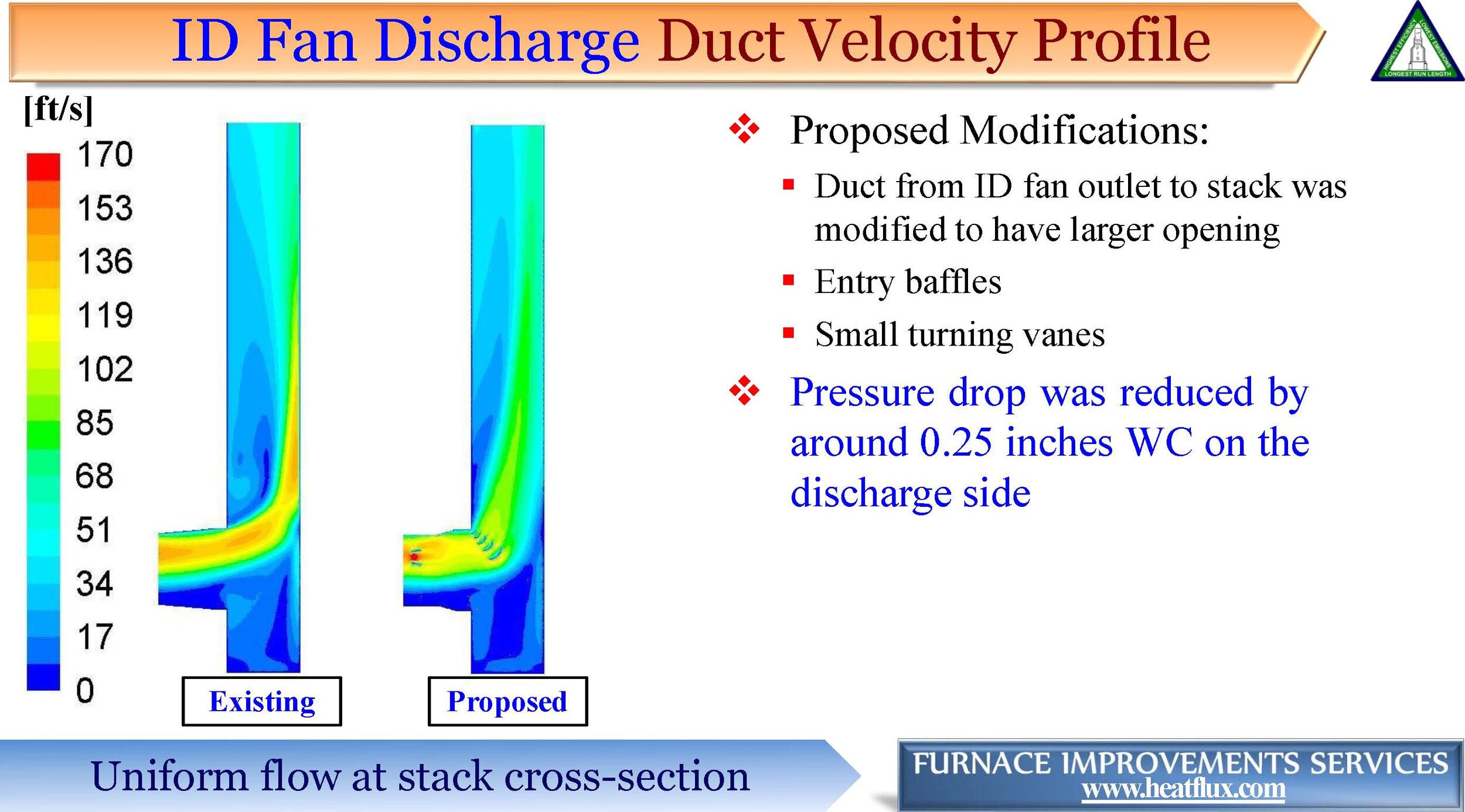

Reduce system pressure losses for ID fan suction and discharge side

This tool enables us to study the existing design and operating conditions of heaters and determine recommendations for solving any difficulties. CFD gives a competitive edge over other analyses due to its visual presentation of the observed conditions and proposed modifications.

Improving Fired Heater Performance Using CFD

Case Study 1: Optimizing Burner Layout by Combustion Analysis

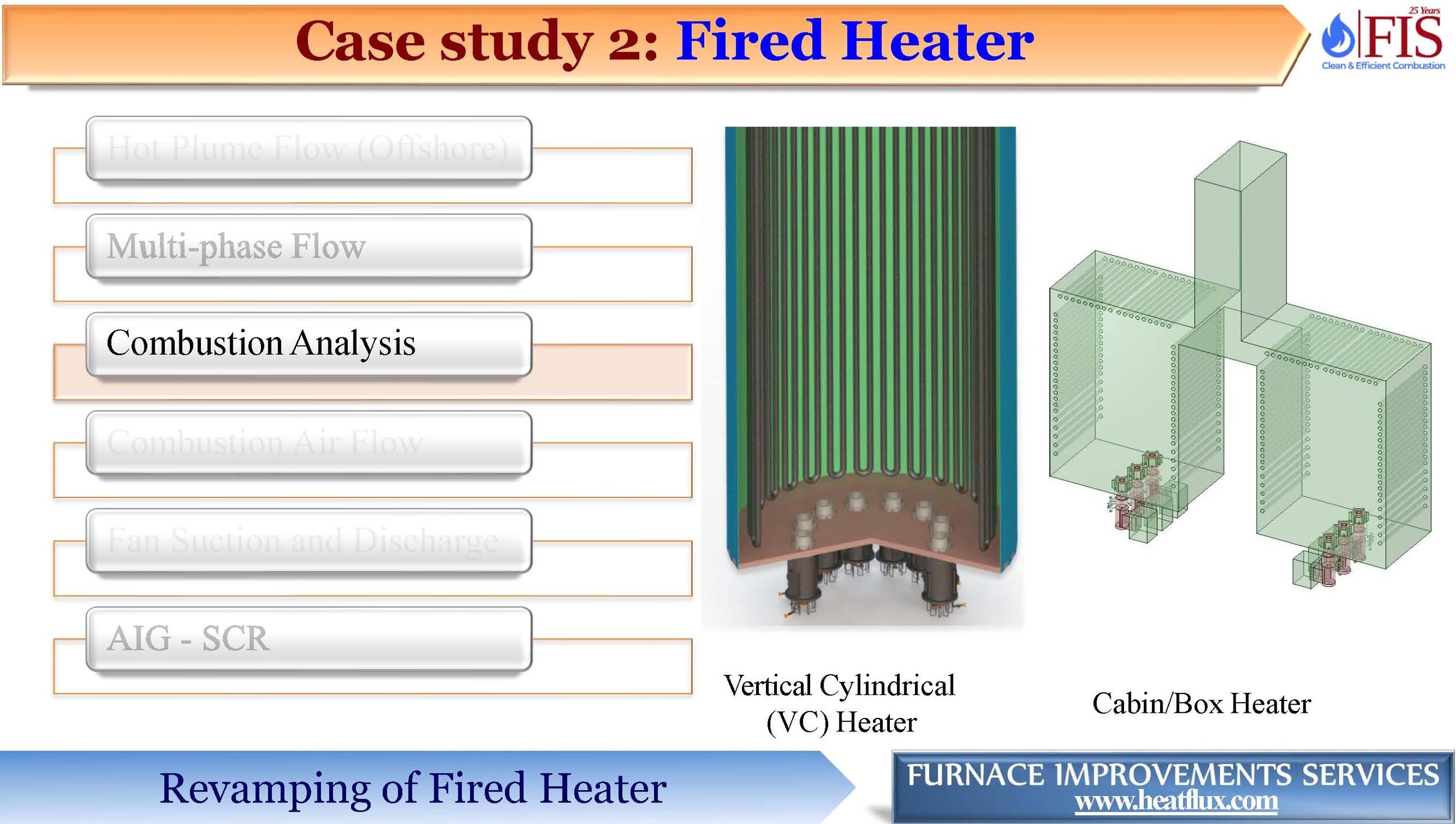

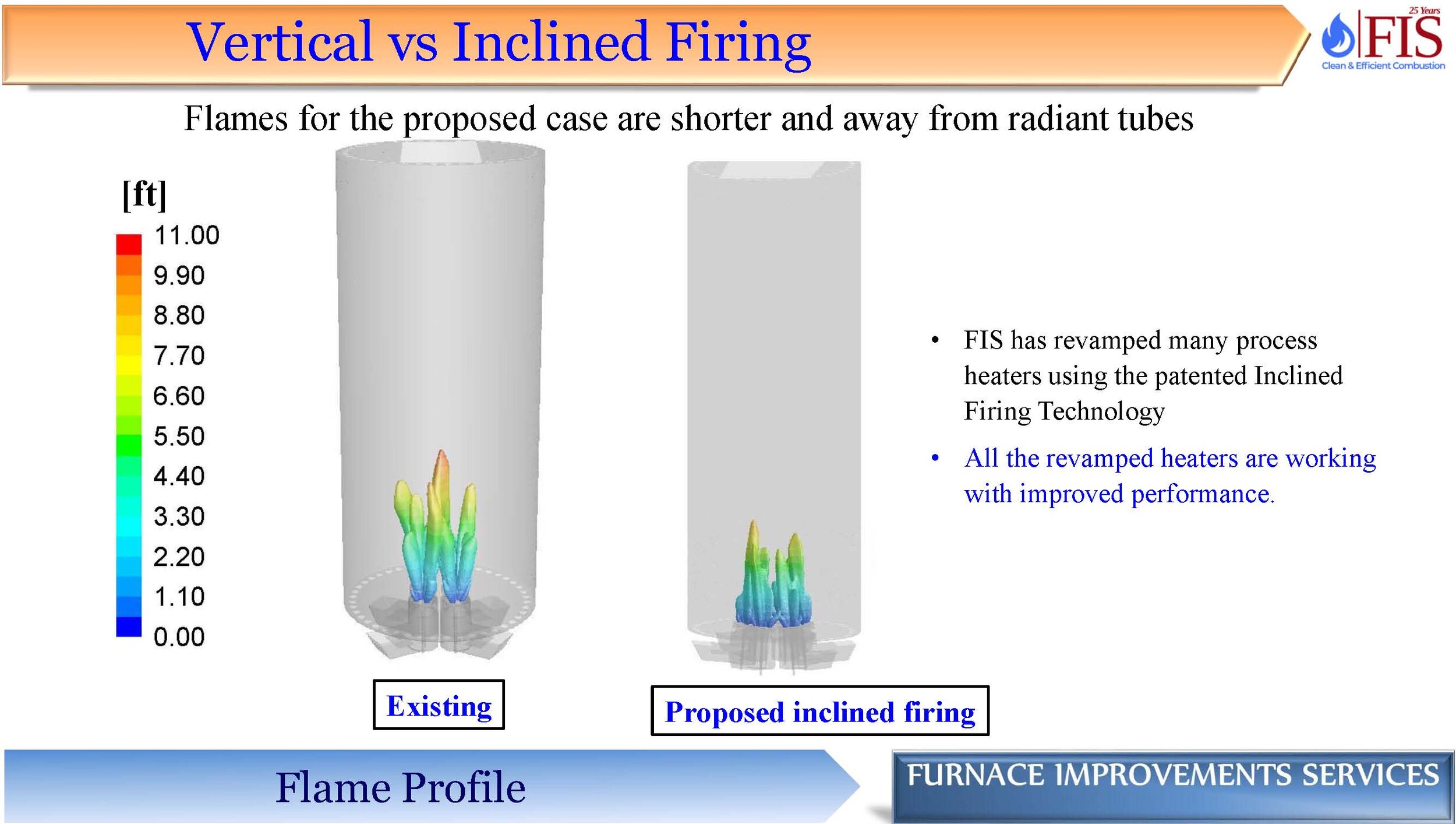

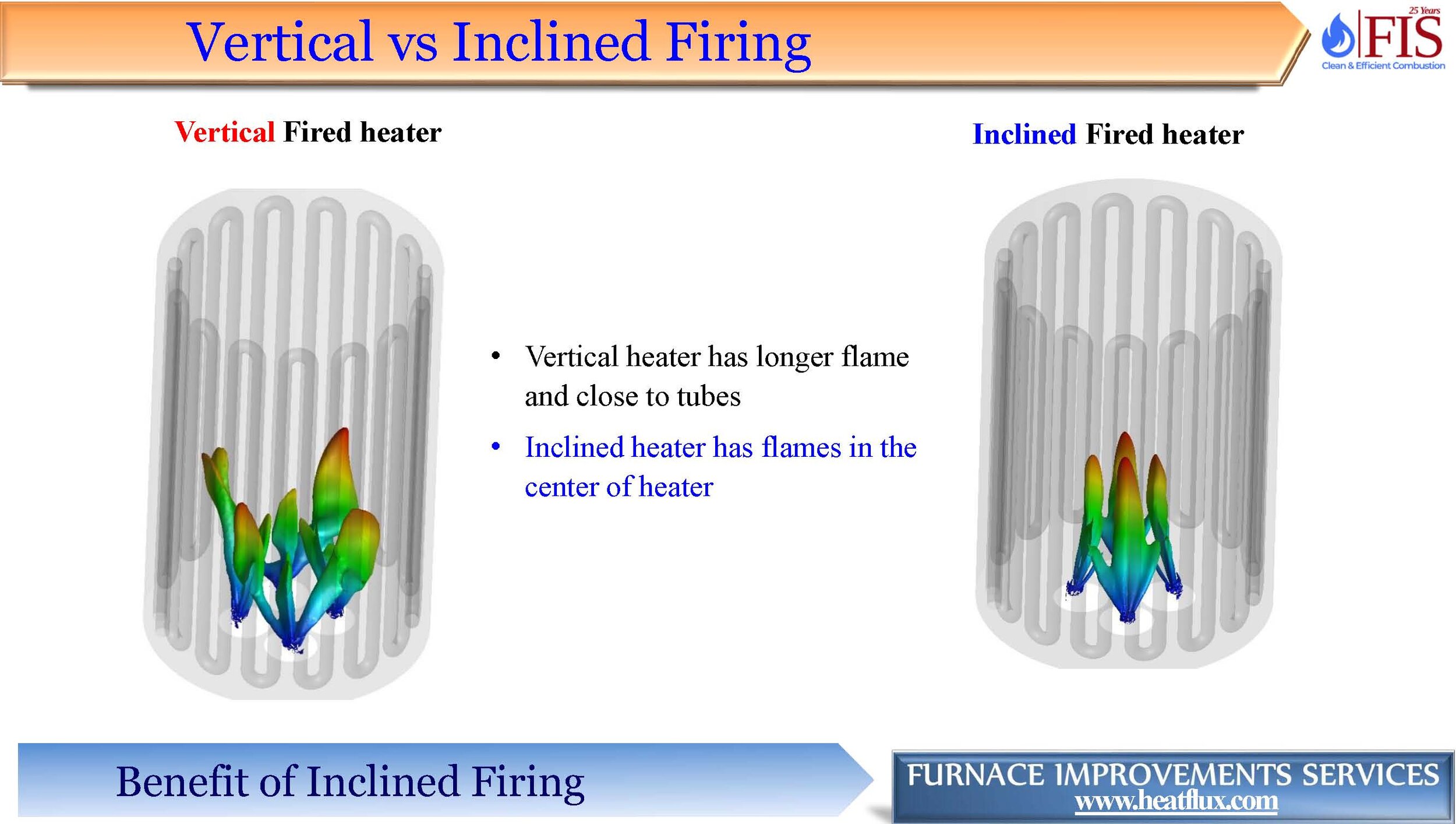

Case Study 2: Lowering Radiant Tube Metal Temperatures with Inclined Firing

Case Study 3: Combustion Analysis of a Cabin Type Heater

Case Study 4: Improving Air Flow distribution across all burners