Hot Oil Heater, Wyoming

Furnace Improvements (FIS) was employed by a refinery in Wyoming to study Hot Oil Heater (HT-501). The Hot Oil Heater was originally designed as a cabin type heater in 1964, for total process duty of 25 MMBtu/hr. Lean oil was heated from 415 °F to 460 °F in the heater and the original design fuel efficiency was 80% (LHV).

FIS analyzed the design and existing condition of the heater. According to the inspection report of FIS, the following points were observed:

Radiant tubes were misaligned, and the tube supports & hangers were in corroded condition

Hot spots were observed in the radiant section

Burner dampers were not in operating condition

Large amount of air was leaking through radiant and convection section of the heater, which resulted in the loss of fuel energy

Based on the above observations, FIS proposed three revamp options:

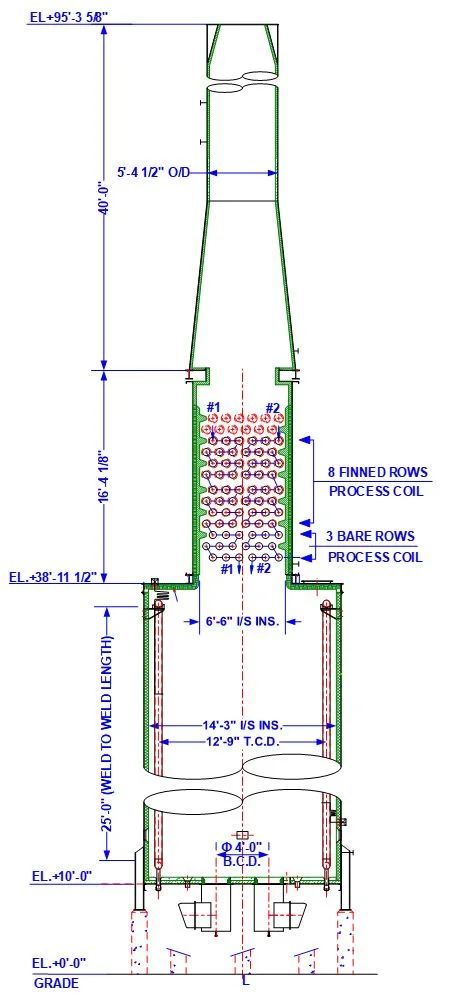

Replacing the heater with new vertical cylindrical heater

Replacing the heater with new cabin heater having the same plot area of existing heater

Revamping the existing heater by replacing:

Radiant coils, refractory and radiant tube supports

Existing convection section with new improved convection section

Burners